As the prevalence of automated equipment continues to grow, so does the need for cable carriers. The applications for steel drag chains remain similar to those of the last century, but incredible strides have been made in automation, robotics, and other light-duty applications that necessitate higher speeds and accelerations. Read on to find information about the plastic cable carriers most often used to meet those requirements.

What Are Cable Carriers?

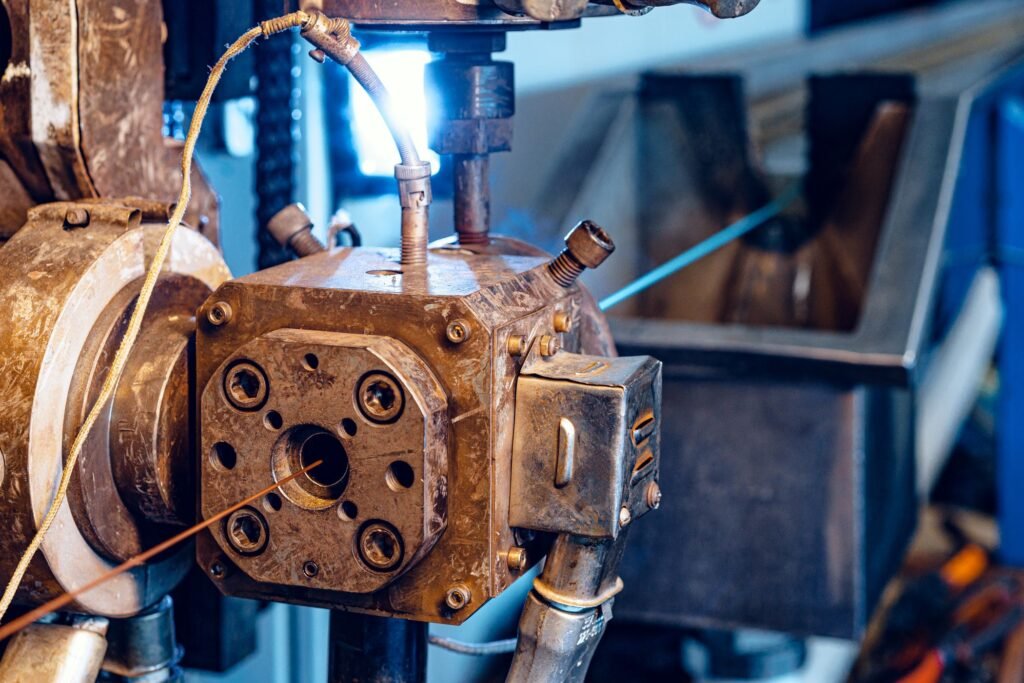

Let’s start at the beginning. Both plastic and steel cable carriers are designed to protect cables, hoses, and hydraulic hoses from damage due to wear and tear, harsh environments, and mechanical operations. They come in many sizes, styles, and designs, but for the sake of simplicity, this article will focus on plastic cable carriers.

A Brief History

Until the early 1970s, all cable carriers were made of steel. While steel is still used today in heavy-duty applications, it doesn’t offer all of the same benefits as plastic when it comes to light-duty applications. As a result, more than half of all cable carriers are now made of plastic.

The Benefits of Plastic Cable Carriers

Plastic is more affordable, easily customized, and able to withstand most environmental conditions. It’s also a better fit for any machine or equipment being operated in a cleanroom environment. Unlike steel, plastic is not subject to corrosion, and some types are resistant to chemicals, fire-retardant, or offer other unique features.

When to Use Plastic Cable Carriers

Plastic cable carriers are ideal in indoor situations that won’t subject the cable and its track to extreme temperatures or harsh environmental conditions. They can be used to carry cables, hoses, or hydraulic hoses safely and are better suited to most light-duty applications. Plastic is also excellent for complex configurations and offers far greater speeds and acceleration than steel.

When to Use Steel Instead

While plastic offers a range of benefits when it comes to cable carriers, it’s not the best option for every situation. Steel cable carriers are required for harsh environments where the cables, hoses, or their carriers could be subjected to temperatures above 240 degrees Fahrenheit or be hit by flying debris. In most cases, steel is also the best choice for applications that require long, unsupported spans because it offers a better strength-to-weight ratio.

What to Look for in Cable Carriers

There are a lot of options out there, so buying the right plastic cable carriers requires doing some research first. Be sure to work with reputable suppliers and ask for the manufacturer’s specifications to be sure that the products will be safe to use in any particular application.

Modern plastic cable carriers should feature a good strength-to-weight ratio, affordable pricing, and pinch point reduction. For large hoses or cables, look for products that support greater link heights. For those that require frequent maintenance, choose either an open carrier or a closed-style carrier that offers easy access.

Find the Right Supplier

There’s good news for people who still aren’t sure if plastic cable carriers are a better option than steel. Dynatect is a well-known, reputable brand that sells a wide variety of carriers made from many materials. Contact their team of experts to ask questions, request the manufacturer’s specifications, or place an order today.